Traffic patterns on farms and around feed centers can potentially be very hazardous from a safety standpoint. There is a lot of heavy fast-moving equipment in action. It is very important keep the on-farm mixing and delivery traffic away from off-farm deliveries. This is important for several reasons. One, we don’t want to slow up the feeding process by waiting on a delivery to be unloaded. Second, there is a safety issue if these vehicles are traveling in the same area. Third, it may not be an issue now but as the industry changes it will be important to separate all on-farm traffic from off-farm traffic for a biosecurity reason. When designing these large operation feed centers this has to be thought about.

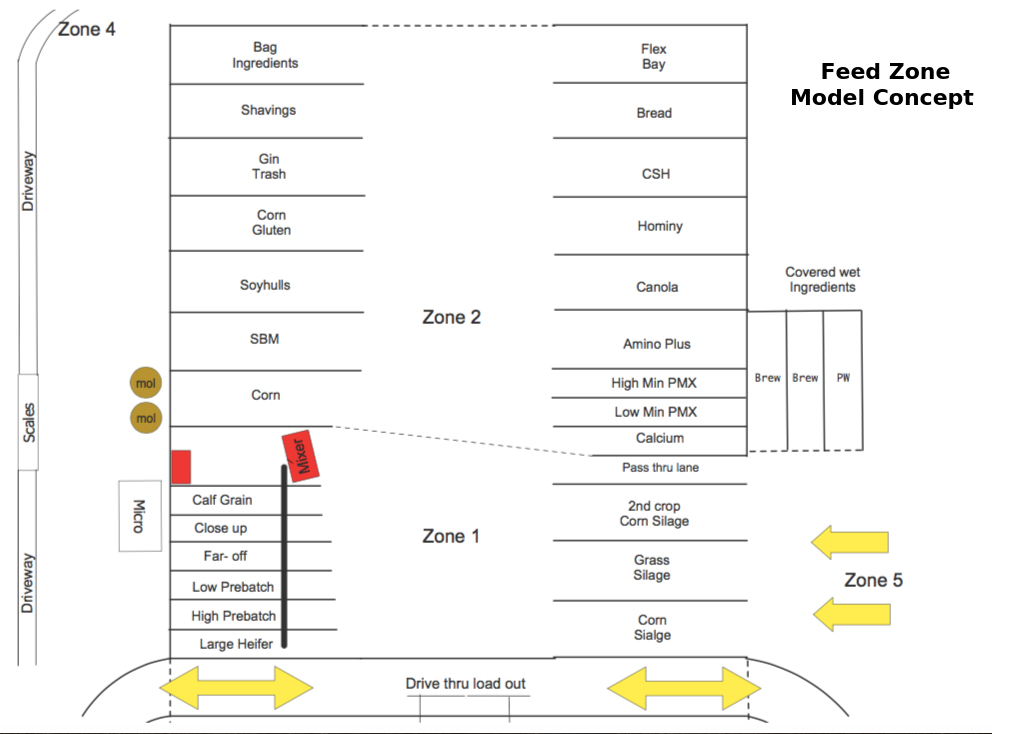

Other things we have to do is maximize efficiency and minimize shrink. This zone concept takes that into consideration. Here are the zones described by actions that are done in each area:

Zone 1 – this is where all TMR loads are made. There should be no other traffic in this area

Zone 2 – this is where all loads are delivered and does not interfere with loader traffic

Zone 3 – this is the on-farm delivery traffic area. If possible, the farm delivery traffic doesn’t need to be in the same path as incoming delivery trucks.

Zone 4 – this is the traffic pattern area for farm deliveries. It should cross the platform scales and enter the feed center in Zone 2 and not Zone 1 or 3.

Zone 5 – This is the forage staging or movement area

This is a very simple concept and way to keep in mind when laying out a feed center. It may be difficult at time when a facility is being expanded or having to build a feed center in the middle of an existing operation. Traffic patterns must be taken into account when designing a facility.