TMR Mixer Dust Entrainment System

The Lid is a patented dust entrainment system that decreases over 75% of the free dust being lost during the loading process of TMR mixers. It is built on the concept of using baffles to slow down exchange air that is being lost while loading ingredients in any type of TMR mixer.

Benefits of The Lid

Proper loading – Makes the feeder load in the center of the mixer where the industry understands that mixers will mix more consistently if loaded in the center.

No over-filling of mixer – This is one of the biggest problems that occurs in feeding operations. TMR Mixers are constantly over-filled. When this happens, the mix will not be consistent, and animals will not perform to the expected/desired level.

Reduce environmental hazard – It minimizes the free dust in the air.

Better maintenance on feeding equipment because of less free dust.

Promote Healthier employees – Less dust in the work area is healthier on employees.

Reduce fire risk – If there is less dust in the feeding area, there is less risk of fire.

Shrink – Allows producers to gain the value of their investment.

Ration Accuracy – Less ingredients being blown away allows the proper ration to be fed to the animals.

Nothing mechanical – The design is built with no moving parts so there is no maintenance or risk of breakdowns.

Can be utilized on all types of mixers vertical, horizontal, reel, etc.

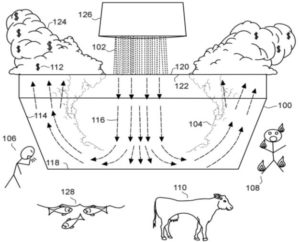

Diagram 1. Illustrates the dust flow exiting the mixer during the loading process.

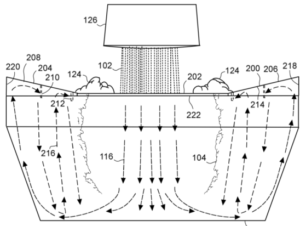

Diagram 2. Illustrates the dust flow with the entrainment system in place greatly reducing the free dust escaping the mixer.

Nothing Mechanical

The Lid is designed to be maintenance-free.

If the unit is damaged, each piece is replaceable.